Escogiendo la relación de transmisión correcta-Video

Existen tres razones principales para reemplazar los engranajes de tu vehículo. El primero es para recuperar la capacidad de la conducción y la eficiencia de combustible de un vehículo de conducción diaria que ha sido modificado con rines y llantas más grandes. El segundo es afinar las características de rendimiento de un vehículo que es dedicado para todoterreno, donde el enfoque está más en el poder y la aceleración. El tercero es mejorar la eficiencia del combustible. El video adjunto describe el por qué y las consideraciones que deben tenerse en cuenta para encontrar la relación de transmisión correcta para su vehículo.

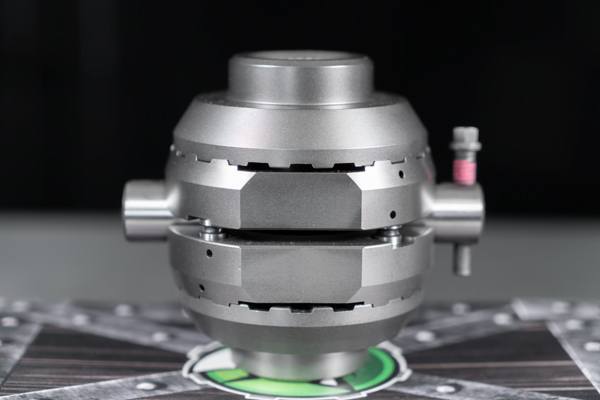

How It Works: Lunchbox Lockers

The Spartan Locker, USA Standard Gear’s lunchbox locker, provides game-changing traction at a low cost. A locker physically joins the drive axles together so they deliver an equal amount of torque to each tire, regardless of available traction. Lockers come in two flavors… selectable or mechanical. What are the Different Types of Lockers? A selectable locker is an on-demand unit that the driver activates electronically or pneumatically via a cockpit-mounted button. A mechanical locker is always active, providing traction 24/7. The Spartan Locker and Yukon Grizzly Locker are mechanical. The Yukon Zip Locker is an air locker or selectable locker that uses a pneumatic system for actuation. The Spartan Locker is flanked by a Yukon Grizzly Locker (left) and a Yukon Zip Locker (right). In mechanical lockers, also called automatic lockers, on-throttle driving conditions, where load is applied to the differential, induces locking. Off-throttle situations, where the diff is unloaded, leads to a partially unlocked unit. When the vehicle turns and the two wheels on the axle turn at different speeds, the unit makes a clicking sound as the square-cut side gears move over and past one another. This ratcheting sound can be loud and is why mechanical units may not be best suited for vehicles that spend a lot of time on the street… it all depends on how sensitive your ears are. What’s for Lunch? The lunchbox locker name is a loose reference to that handy mid-day meal carrier we all know and love. Just as you can put a different kind of meal in your lunchbox, the lunchbox locker allows different internals to be put in your differential… the internals being the lunch and the differential carrier being the box portion of the equation. Lunchbox lockers are not a singular component you swap in, but a collection of parts that converts an open differential carrier (and only an open differential carrier) into a mechanical locker. A typical Spartan Locker consists of a pair of drivers, two spacers, two side couplers, four alignment pins, four pre-load springs, a hardened cross-pin shaft, a roll pin, and installation wires. Depending on the differential carrier design, your Spartan Locker could have more or less components in the box. Pros and Cons of Lunchbox Lockers Great grip on a budget is the lunchbox locker’s calling card. Price is the biggest pro for the lunchbox locker. They cost less than half the price of an air locker, and remember this is before factoring in the cost of a pneumatic operating system. The lunchbox locker is about a third of the price of a large-frame mechanical locker / automatic locker. Going with a lunchbox locker also pays off when it comes to installation. Since the process is less labor intensive than a large-frame locker installing a lunchbox locker costs less. The savings can be even more substantial if you handle the install yourself. The Spartan Locker's patent-pending design replaces the spider gears in a standard carrier case, does not use the thrust washers, and has a revolutionary spring-and-pin design that makes installation quick, easy, and much cheaper that other types of lockers! Further, in some cases, the install does not require the removal of the differential. A disadvantage of this is the lunchbox locker relies on the factory carrier for strength. Large-frame lockers, like the Grizzly and Zip, replace the carrier as a single unit and their case is constructed from a much stronger alloy steel compared to the factory carrier. Being locked all the time, mechanical lockers can cause accelerated tire wear. As with many modifications, it’s a game of trade-offs. Installation Tips and Tricks If you’re able to remove the spider gears with the carrier still in the housing the installation can be done without removing the carrier from the diff. If it’s too tight in there, the diff will have to be removed. Spartan Lockers come with a highly detailed installation manual that includes tons of photos and step-by-step instructions. The manual addresses installation in a variety of differentials. Basically, the Spartan Locker’s drivers are assembled with the alignment pins and springs installed. The installation wires keep the assembled unit together until installation is finalized then they’re removed releasing the spring tension that’s needed to operate the unit properly. Spartan Locker Installation Quick Tips For Use in Open Differentials Only Remember to Re-Install Carrier Shims and Bearing Caps in the Same Place Punch Mark Bearing Caps to Indicate Which Side to Install Them On Be Sure Tires are Same Circumference to Ensure Proper Locker Engagement Are Lunchbox Lockers for You? Vehicle usage is the tipping point. Not just how much your rig will see the street where the boisterous operation of the lunchbox locker comes into play but off-road usage as well. Your expectations on the trail; and how much you’ll be demanding from the driveline come into play. If you’re staying on the trail with moderate hill climbing, scrambling over rocks, and the like, the lunchbox is a good call. If you plan to be more aggressive and looking to get into some extreme situations where a great deal of torque and load shocking are the norm, a large-frame locker may be the way to go. When it comes to the ratcheting and clunking sounds the unit makes, read up on the subject. Some users report the sound isn’t that intrusive, others say the noise fades with use. As we indicated before, the performance game is made of trade-offs… but the payoff is big. Spartan Locker Highlights Big on Traction, Low on Cost For Use in Open Differentials Only Patent Pending Design Replaces Spider Gears Low-Cost Shop Installation - Can be DIY Installed Reliable 100% Lockup Power Transfer Features Heat-Treated 9310 Steel Internals for Enhanced Durability Shop Spartan Lockers or contact us at 866-631-0196

How It Works: Yukon Dana 30 CAD Delete Kit

What is CAD? What is CAD? It’s not short for Cadillac… In this case it’s not the acronym for Computer Aided Design… For our purpose CAD stands for "Central Axle Disconnect." At its core, the Yukon Dana 30 CAD Delete Kit blocks off the vacuum actuated engagement of four-wheel drive in Dana 30 differentials. Select Jeep vehicles produced from 1984 to 2001 are equipped with the automaker’s reverse rotation Dana 30 differential that’s outfitted with the Central Axle Disconnect (CAD) system. The system components, located on the passenger-side axle tube, consist of a two-piece splined shaft and a coupler that a vacuum-operated shift fork actuates to connect or disconnect the axle, which engages or disengages four-wheel drive. Dana 30 Heritage The Dana 30 has been the go-to front diff for the Jeep Wrangler since the model’s Jurassic Period… CJ-5 models of the early 1970s. Available in high- and low-pinion versions as well as standard and reverse rotation versions, the Dana 30 is an important building block in the Jeep hierarchy. There are tons of aftermarket parts for this differential and spares waiting for rescue in junkyards across the country. CAD Versus The Elements Time is no friend to the CAD system. The vacuum lines can crack, the vacuum motor can fail, or the system can be compromised in another manner, and cause the Jeep to be stuck in two-wheel-drive… that’s no fun. Further, the two-piece axle is not as strong as a one-piece design. Fortunately, the stronger and more reliable one-piece axle from a TJ or ‘non-disconnect’ XJ are direct swaps. The catch… sealing the housing post-swap. Yukon To The Rescue Enter the Yukon Dana 30 CAD Delete Kit. It consists of a disconnect housing blocking plate, gasket, and inner axle seals that will accommodate a one-piece axle design. Yukon Dana 30 CAD Delete Kit Applications 1984 - 2001 Jeep Cherokee XJ 4WD 1984 - 1998 Jeep Cherokee XJ Sport 4WD 1986 - 1992 Jeep Comanche MJ 4WD 1984 - 1991 Jeep Grand Wagoneer ZJ 4WD 1993 Jeep Grand Wagoneer ZJ 4WD 1987 - 1995 Jeep Wrangler YJ 4WD End Of The Trail The Dana 30 has been around since the prehistoric days of the Jeep brand… and it’s not going anywhere. Neither is Yukon Gear & Axle. We have a vast inventory of replacement parts that will keep Dana 30s on the road and performance products that will improve the breed. Happy Wheeling. contact us at 866-631-0196 Shop CAD Delete Kits

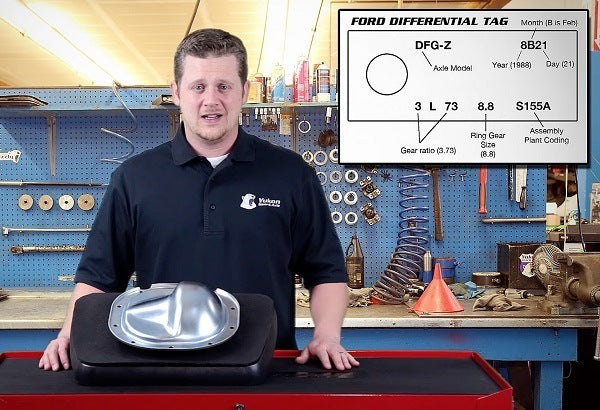

Decoding Differential Tags - Video

Auto manufactures have made it possible to glean basic but useable differential information by means of tags, stickers or stampings on the differential. The tags are usually affixed to the pumpkin by a diff cover bolt and stickers can be on the housing or axle tube close to the housing. The “direct from the source” aspect of this information makes it hyper accurate, overriding any confusing make, model, engine, and transmission information mash-up. No late night research needed. It’s all right there, straight from the manufacturer. The accompanying videos outline what info is on Ford and GM tags and what it means to you.

The Sounds Of Death: A Failing Differential Story

Breaking a differential can be a sudden, horrific event. If you’ve haunted the drag strip you’ve undoubtedly seen the loud, fully cammed hot rod drop the clutch then drop a load of gears and metal on the track. Out on the trail, a struggling rig finally hooks up and the sudden torque is too much for the diff, grenading the unit to its ultimate demise. Read this article in Español A differential can also die slowly and alert you to its impending doom. A vehicle in motion makes many different sounds, most are relaying a harmonious state of being. But there can be tremors in The Force. As things start going sideways in a differential there are noises that serve as clues to what’s happening and knowing the what the noises mean will help you determine what may be wrong. To this end, we are offering this rundown of common noises and their likely point of origin. The Sounds Of Death A “whirring” sound generated by unloading via deceleration from most any regular road speed can likely be traced to pinion bearing failure or poor pinion bearing preload. This malady is often diagnosed as a bad ring and pinion gear. Generating a “whine” or “howling” sound under positive load i.e. acceleration is more in line with a worn or failing ring and pinion gear or a ring and pinion gear set that has not been setup correctly. If you detect a “rumbling” sound at speeds above 20 mph that tends to change frequency while the vehicle is turning it may be caused by worn carrier bearings. But it could also be bad wheel bearings. To confirm, jack up the vehicle at the offending corner and shake the tire. If there is a lot of play in the wheel/tire, the wheel bearing is most likely the culprit. [At Left: Here’s a real screamer. Crush sleeve or pinion bearing failure resulted in the pinion gear trying to eat the carrier.] A regular rhythmic “clunking” or “clicking” detected every few feet may be a broken tooth on your ring or pinion gear. If you have recently swapped on new rolling stock, check the inside of the wheel for an exposed clip-on external wheel weight that may be hitting the shock body on every revolution. A more aggressing “clunking” that borders on “banging” that happens when cornering may be caused by broken spider gears, poorly lubricated limited slip differential or positraction units, or worn clutch packs in limited slip differential or positraction units. Basic Ground Rules In this process hearing the sound is easy enough… it’s tracing the source that gets tricky. The big challenge is discerning a failing bearing within the diff to a wheel bearing that is going south. The sound is similar. One of the determining factors is the fact that the wheel bearing noise will change with wheel speed but usually will not change with load variations i.e. acceleration or deceleration but the sound from a wounded rear differential will change with wheel speed and load. Listen with Your Eyes Leaks are warning signs too. They can be precursors to trouble or the result of trouble. While some fluid under the vehicle can be part of condensation from normal operation, noticing reddish drips can be a sign of leaking transmission fluid. A compromised seal or gasket steals away vital lubrication resulting in dry, overheated internals and impending failure. The bottom line here is any noise emanating from your drivetrain, whether you can locate its root source on not, is serious business. Tracking down the cause is critical to prevent more serious damage and more expensive repairs. For more insight into the Sounds of Death, check out the accompanying Identifying Ring and Pinion Gear Noise video.